Do you love vintage racing bikes? Are you a bit eco-conscious and don't want to buy a new bike? Do people say you’re "tight with money"?

But most importantly, you don’t want to invest in a fancy bike that, like many nice bikes in the city, will likely get STOLEN.

Then we have the solution for you: restore an old 80s racing bike to turn it into a little speed machine.

Sure, it’ll be a tad heavier than a brand-new bike owned by a 30-something triathlete, but it’ll ride well... and most importantly, you’ll be much less likely to have it stolen.

Step 1: Buying a racing bike on the internet

Personally, I set my sights on a small Gitane bike for 70€, size 54, worn by life, but just needing a little love to reveal its full potential.

Regarding the size, note that 54 is versatile enough for anyone between 1m68 and 1m85.

Find below a chart explaining how to choose the frame height (from the center of the bottom bracket to the bottom of the seat) of a road bike:

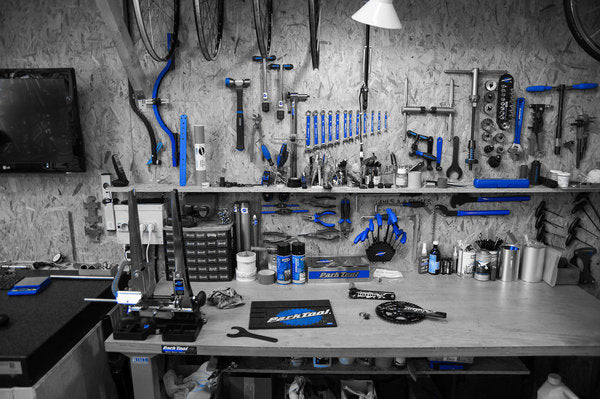

Step 2: Find the nearest repair shop

Three reasons to join a local repair workshop:

- for every repair, the golden rule if you don’t want to pull your hair out is: one repair = one toolset

- you'll find many spare parts that are impossible to find in stores

- best of all, membership usually costs only around €20 per year.

For Parisians, I recommend Solicycle.

Step 3: Change the rim tape and tires to avoid flat tires

To check if a flat tire is due to a worn rim tape, simply check if the puncture is on the underside of the inner tube. If it is, there's no doubt the rim tape is the culprit!

To fix it:

- deflate the inner tube and remove the tire

- check if the rim tape has holes (if so, it's guaranteed to cause a flat)

- if it's damaged, remove the rim tape.

- clean the rim with a dry cloth

- carefully wrap the new rim tape flat, starting from the valve hole

When to change your bike tire?

- every 2000 to 5000 km

- no groove depth on the top

- cracked on the sides

- torn / slashed

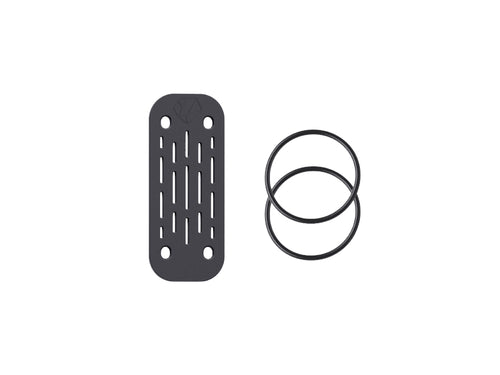

Note

Tire maintenance

- Every 2000 to 5000 km

- No tread depth on the top

- Cracked on the sides

- Holes/tears

Step 4: Change the brake cables and sheaths, the brake pads and apply the brakes

Step 5: Change the cables and derailleur hoses

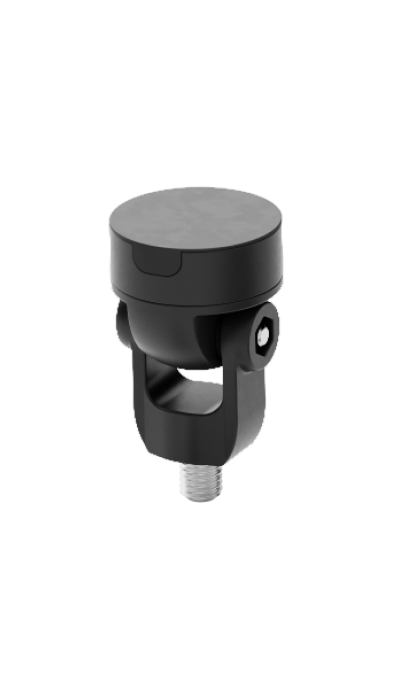

The cables on a road bike typically pass through this type of shifter. They are easily removed by loosening the clamp bolt at the derailleur (front/rear) and then pulling the cable out through the end of the shifter.

See the photo on the right.

--

How to adjust the front/rear derailleur on a vintage road bike?

As with all derailleurs, the task is to adjust the high stop and low stop. On mine, there are two stop screws:

- One screw corresponds to the stop when the cable is tight: the derailleur won’t go any higher

- One screw corresponds to the stop when the cable is loose: the derailleur won’t go any lower

I’ll spare you the diagrams, but the general principle is this: tighten the cable fully and adjust the high stop, loosen the cable fully and adjust the low stop. By playing a little with the screws, you can immediately see if the derailleur moves up or down.

- When the cable is tight, you want the chain to be on the large chainring. If not, give the screw a slight turn to allow the derailleur to move up a little higher

- When the cable is loose, you want the chain to be on the small chainring. If not, give the screw a slight turn to allow the derailleur to move down a bit more

Step 6: Grease the rear hub

Not the easiest operation to perform, but at least you'll be sure your bike will run perfectly after that! But before anything else, you need to understand how a rear bicycle hub works:

- the hub is the moving part of the wheel where the spokes are attached (no need to remove the spokes for maintenance).